Baffle tank containers, commonly known as baffled tanks, offer a range of advantages, particularly in the field of transporting liquid volumes ranging from 20% to 80% of the tank container's capacity. This article delves into the key benefits of these specialised containers, exploring how they contribute to safer and more efficient liquid cargo transport.

Contact us today to discuss your specific bulk liquid cargo requirements and discover how our baffle tank containers with innovative designs can enhance your operational safety and efficiency.

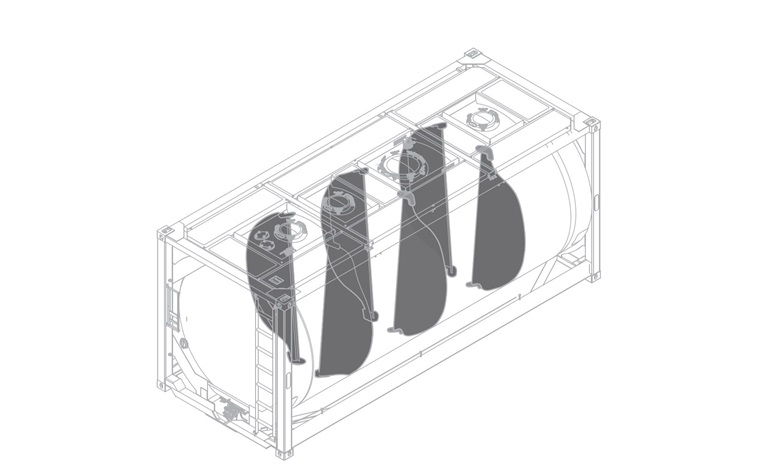

Reduced Cargo Movement

Baffle tanks have internal partitions or baffles that help reduce the movement of liquid cargo during transportation. The prevention of excessive cargo movement is particularly crucial when carrying smaller quantities of liquids with low viscosity/high fluidity.

By minimising the swaying and shifting of liquid cargo, the internal baffles contribute to preventing potential damage to both the container and its contents during transportation, enhancing overall transport safety and stability.

Safer Transportation

The enhanced stability and reduced movement provided by baffle tanks contribute to safer transportation of liquids. This is legally required for hazardous products and especially important for sensitive materials, as it helps to minimise the risk of accidents and potential fines.

Versatility and Flexibility

Baffle tanks are suitable for a wide range of liquid cargoes, including chemicals, food products, and other bulk liquids. Baffled tanks offer the convenience of being loaded within the versatile range of 20% to 80% tank container capacity. This not only enhances flexibility but also provides a practical solution to meet the varied needs of our customers.